Böllhoff

LEO locative for fast and space-saving production processes

About Böllhoff

Böllhoff Production Ltd. is known worldwide for its quality and expertise in fastening and assembly technology. As a reliable partner, the company supplies customers from numerous industries, particularly the automotive and aerospace sectors. To sustainably increase the efficiency of internal processes, Böllhoff is focusing on digital transformation and automation in intralogistics. This reduces manual work steps, streamlines processes, and increases productivity. With innovative technologies and a clear view of tomorrow's requirements, Böllhoff is laying the foundation for future-proof solutions – in line with Industry 4.0.

Background and requirements

- Use of automatic assembly machines to manufacture high-quality finished parts from multiple components

- Storage of replenishment containers directly in the production area – usually on pallets

- Manual processes and long walking distances dominated intralogistics operations

- Market requirements in the automotive and aviation industries demand maximum precision and flexibility

- Walking distances should be reduced to relieve employees and minimize transport times

Efficiency increase at a glance

Success by forming a project partnership

BITO

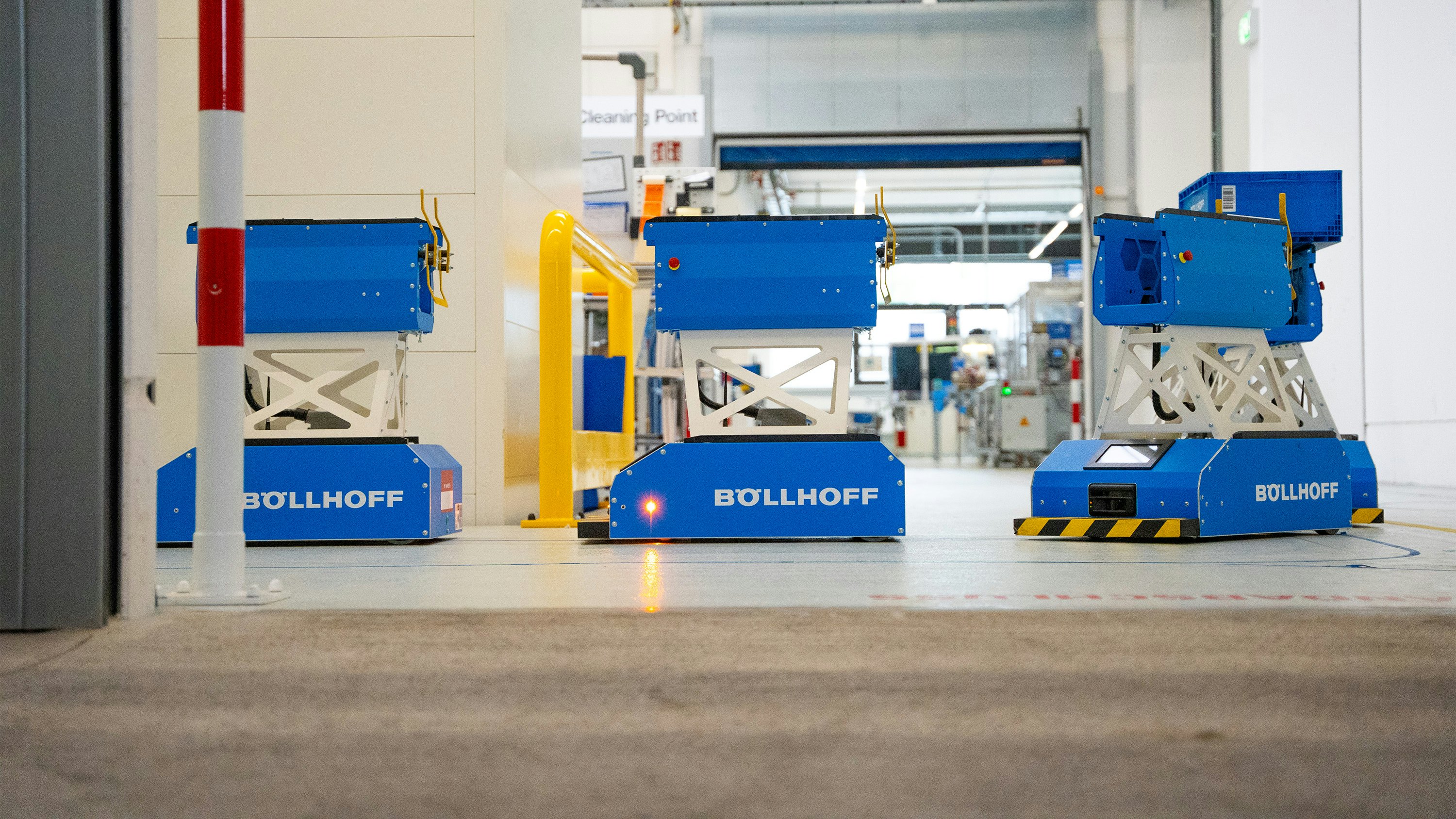

» Nine LEO locative AGVs take care of supplying 25 assembly workstations in three halls.

Kardex

» Two Kardex Miniload-in-a-Box systems are used to store semi-finished and finished parts.

P.S. Cooperation

» The el/ka/sy system from P.S. Cooperation is used for warehouse management.

Customer application

- Collaboration between Böllhoff, Kardex, BITO, and P.S. Cooperation

- Integration of a Kardex Miniload-in-a-Box for space-saving storage of semi-finished parts

- Setup of a 30-hour buffer system for continuous supply to the assembly stations

- Material retrieval at the touch of a button by the employee directly on the line

- Automated retrieval of parts from the Kardex system

- LEO locative takes care of transport to the assembly station

- After completion, the parts are transferred again by LEO locative to a second Miniload unit and stored until shipment

- Control and coordination via the intelligent warehouse management system el/ka/sy from P.S. Cooperation

- Efficient combination of automation, logistics technology, and digital control

Customer benefits

Thanks to the collaborative solution, the following benefits were achieved:

- Reduced walking distances for employees, resulting in improved workplace ergonomics.

- Staff are assigned to more value-adding tasks.

- Direct connection of the LEO system to the Kardex Miniload-in-a-Box conveyor technology to ensure autonomous container exchange.

- Integration into the Böllhoff network for the transmission of transport orders.

- Increased efficiency, reduced errors, and space-saving storage.

'From Böllhoff's perspective, we can ultimately say that the major digitization project we have completed has truly fulfilled all of our expectations. Working together with Kardex, P.S. Cooperation, and BITO, all of our requirements for a fully automated digital process have been completely implemented. […] The BITO LEO transport system has enabled us to fully automate our material processes. We no longer need to manually intervene in the supply and disposal of the assembly systems.'