Wilkinson Sword

LEO flow for fast and space-saving production processes

About Wilkinson Sword

Wilkinson Sword GmbH, based in Solingen, is a long-established company in the cutlery industry and part of the international Edgewell Group. Since the site was established in 1961, high-quality wet razors and razor blades have been produced here – both for the Wilkinson Sword® brand and for the global market. With over 500 employees and state-of-the-art manufacturing technology, Wilkinson Sword is one of the leading manufacturers in the industry and stands for quality “Made in Solingen.”

Background and requirements

- Production of several billion blades per year using highly automated manufacturing processes

- Daily demand for several million plastic parts for blade assembly

- Empty containers must be provided regularly and brought to the machines manually

- Storage and provision of empty containers has been done manually up to now

- Employees walk several kilometers per shift to supply the machines

Efficiency increase at a glance

The BITO solution

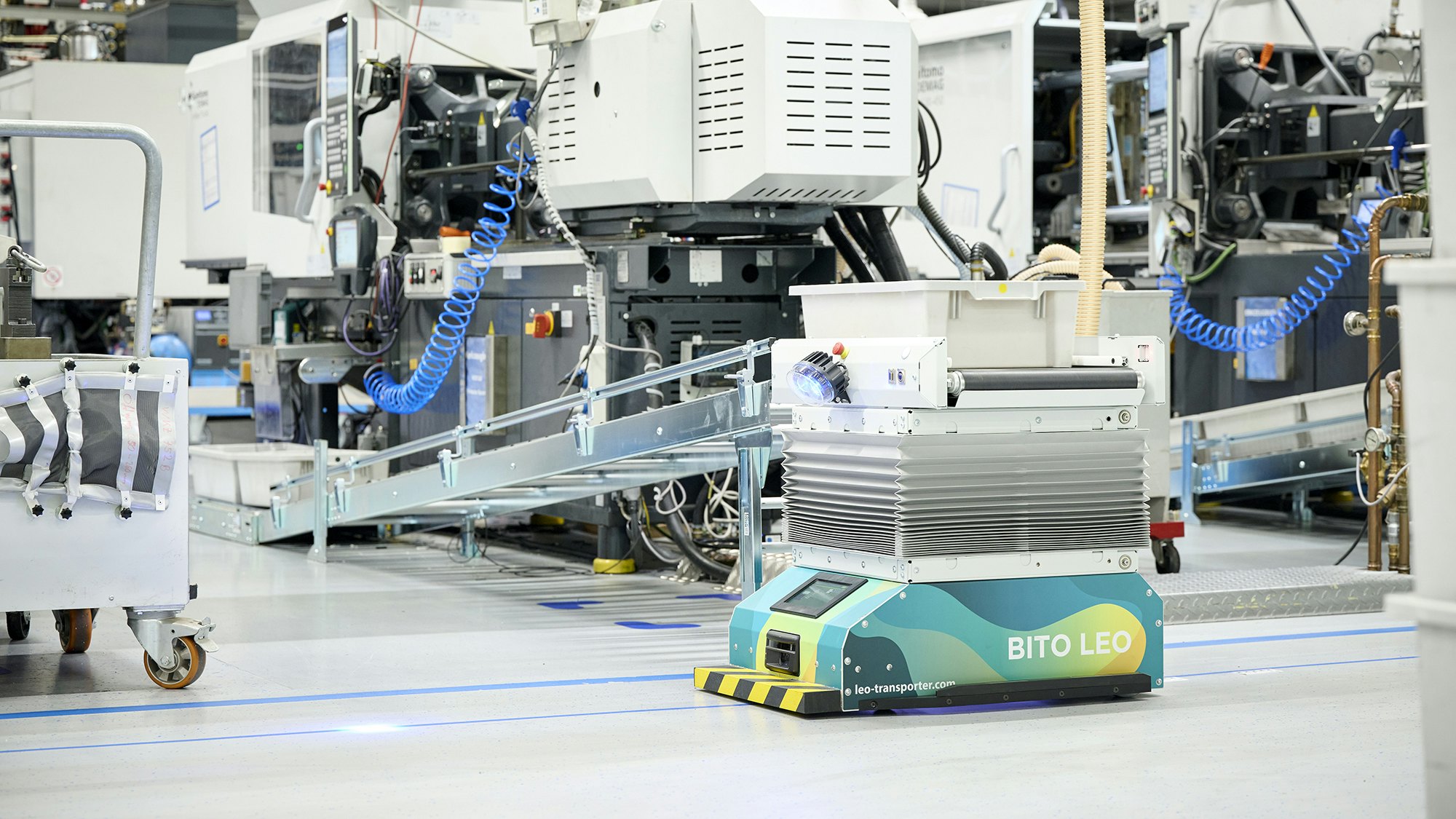

LEO flow

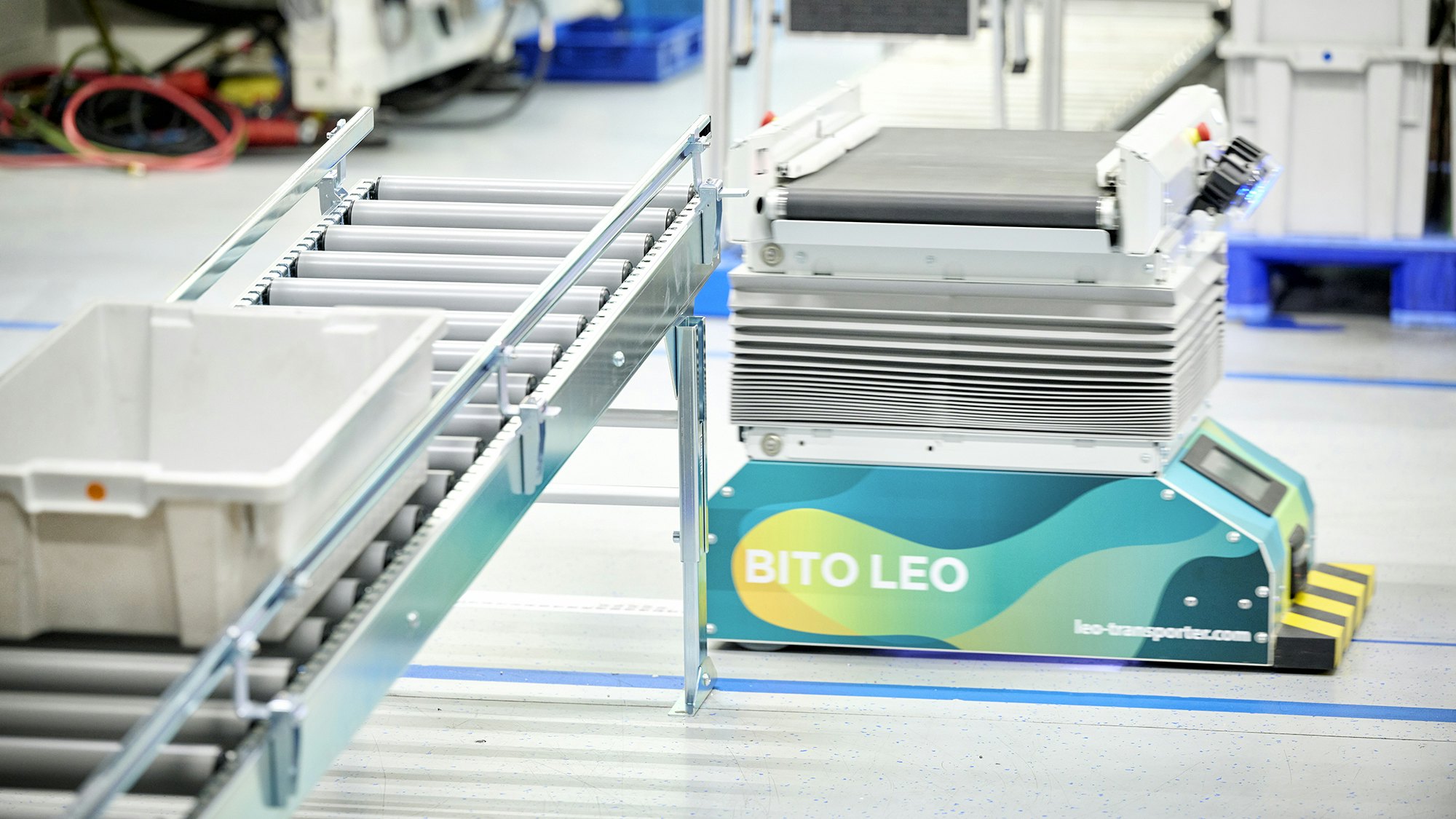

» The autonomous transport system that picks up empty containers, shuttles between buffers and machines, and supplies them as needed. LEO flow features dynamic height adjustment and operates fully automatically.

Gateway

» The central communication interface that receives all demand requirements and coordinates the control of the LEOs. It connects machines, smart boxes, and LEOs with each other.

Smart Box

» The smart interface on the machine uses light barriers to detect when a new container is needed and automatically reports the requirement to the gateway.

Customer application

- LEO drives to the empty container buffer, where stacked containers are waiting

- The containers are separated on site – LEO picks up a single empty container

- LEO drives the container to its defined waiting position near the machines

- LEO waits there until a machine signals via a light barrier that a new container is needed

- The machine's smart box automatically sends the request to the central gateway

- LEO receives the order and drives to the corresponding machine

- LEO transfers the empty container precisely and automatically on the mounted roller conveyor

- The transfer is height-adjusted – LEO's belt conveyor is moved vertically via a scissor lift unit

- This allows different conveyor heights to be served flexibly

- After the transfer, LEO returns to the empty container buffer, picks up a new container, and returns to its waiting position

Customer benefits

Thanks to the BITO solution, the following benefits were achieved:

- Manual processes have been largely automated by LEO – for greater efficiency and fewer errors

- Employees are relieved of specific tasks – walking distances are eliminated and physical strain is noticeably reduced

- Getting started with autonomous intralogistics is easy and safe – ideal for those taking their first steps toward automation

- Reproducible transport processes ensure consistently high supply reliability

- Travel routes can be adapted flexibly and quickly – ideal for dynamic production environments

- System integration is particularly user-friendly – easy to implement even for newcomers

- Machines are supplied with empty containers automatically and as needed – without waiting times

- Scalable system – expansions and new areas of application can be implemented at any time

- Digital control via gateway and smart box increases process reliability and transparency

- Space-saving solution – ideal for complex production layouts with limited space

‘We chose the LEO from BITO because it is so easy to integrate. The required routes can be easily defined using the supplied track tape and changed at any time. This makes the system very user-friendly during the setup phase, especially for newcomers. LEO will definitely be part of the next expansion phase.’