We have the right solution for your needs

The BITO LEO transporters have already convinced a large number of customers with numerous solutions in various application areas in production. In order to always meet the needs of our customers and the dynamic market conditions, we are constantly developing our products further to expand our product family. To be able to offer a solution for diverse applications, our product range consists of three BITO LEO transporters.

Whether LEO locative, custom or flow - the various BITO transporters fulfil almost every requirement in terms of material flow automation

- LEO locative ideal for trays, containers and cardboard boxes

- LEO custom ideal for customers who require customised solutions for their processes

- LEO flow ideal for applications in combination with conveyor technology

Book an appointment!

Use our online booking calendar to arrange an appointment with our BITO LEO experts.

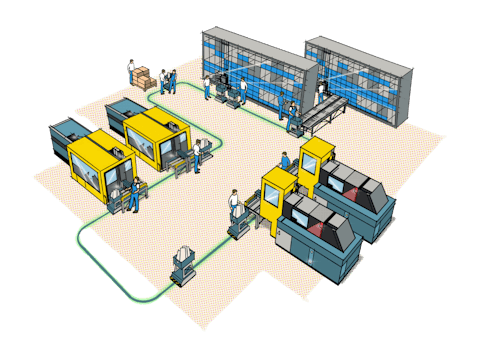

Applications in various areas of production

Production machines are constantly supplied with raw and packaging materials, semi-finished products and tools. The produced parts must then be transported to the next production steps for further processing or to the outgoing goods warehouse. Waste materials or quality samples also need to be transported. The BITO LEO transporters are ideal for automating these transports. This makes manual transport and walking routes for employees obsolete. The LEO system can be loaded manually or connected to the machine via transfer stations.

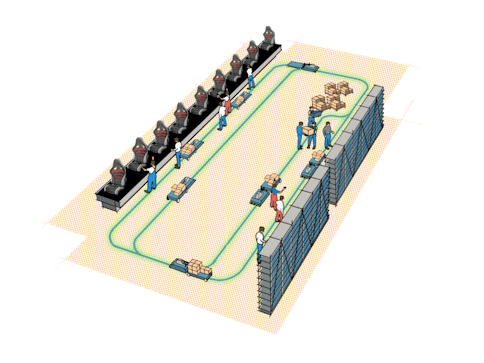

To avoid production downtimes, assembly lines must be continuously supplied with materials. These are often pre-picked in so-called supermarkets and then transported to the lines in containers, on transport trolleys or special trolleys. The empty means of transport must then be returned to the warehouse to be refilled.

The BITO LEO AGV system offers a range of options for automating these transports.

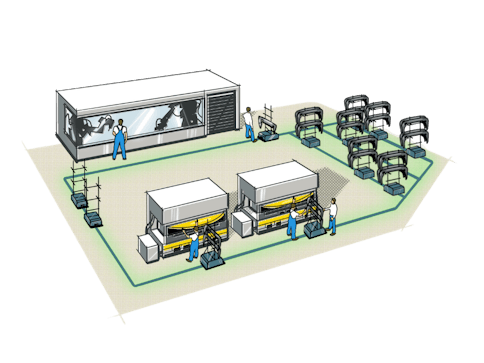

Conveyor belts are often used in production to link several production steps together. However, investing in these is very expensive and inflexible. This is why platform AGV systems are increasingly taking over the function of assembly lines.

LEO custom is suitable as a solution to this problem thanks to its application-optimised superstructures and can therefore take on the role of the assembly line more cost-effectively and flexibly. LEO custom can also fulfil additional tasks such as transporting finished goods to the outgoing goods warehouse.

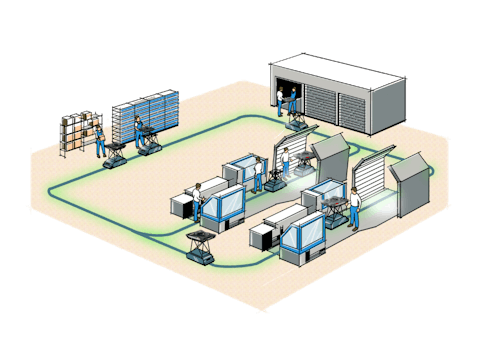

Buffer warehouses are very often used between the individual assembly and production steps. This simplifies individual work processes, as goods often have to be placed in a different order, cooled or matured. The BITO LEO transporters have already proven themselves as mobile warehouses in the past. One specific example of this is the transport of bumpers. These were moulded for various models and then pre-sorted for painting.