What is LEO locative?

LEO locative automates the transport of containers, cardboard boxes and trays. The system does not require an IT connection and can be implemented and expanded by customers themselves. One of the special features of the system is the load pick-up of the transporter and the associated transfer stations. Containers can be dropped off and picked up without any loss of time as they pass through the stations.

- Payload of max. 35kg

- Does not require an IT connection

- Patented transfer system for picking up and dropping off containers

All information about the BITO LEO

Information, tips and advice on the BITO LEO

Download LEO Profi

Discover valuable information about the BITO LEO! Download this free document and get useful tips and advice. Use this practical resource for a comprehensive overview and in-depth insights into all LEO products.

Download the document now!

Just one more click. To send you the requested document by e-mail, we need your name and e-mail address:

Leadmagnet Default Form

Done! The requested document is on its way to you.

If you do not receive the email in your inbox, please check your spam or junk mail folder.

LEO Locative in action

Book an appointment!

Use our online booking calendar to arrange an appointment with our BITO LEO experts.

Which applications is LEO locative used for?

LEO locative supports you in numerous areas of production logistics and goods distribution

Connection between production and order picking

Support for decentralised order picking

Supply of machines with raw materials

Removal

Have we aroused your interest?

Please feel free to contact us. We look forward to your enquiry:

The LEO transporter is able to drop off and pick up containers by simply driving through a LEO transfer station. Even empty cartons remain safely in position during the journey.

LEO locative is optimised for containers and cardboard boxes.

The LEO transfer stations can pick up containers from LEO and deliver them to it. The transfer stations are available as single stations and as double stations, which allow containers to be picked up and dropped off at the same time.

In conjunction with the transfer stations, the spring-loaded towing mechanism ensures automated, but purely mechanically functioning container pick-up and drop-off. The carrier of the transporter is either folded down to release the container from the transporter or fixed in place to pull the container from the station onto the LEO.

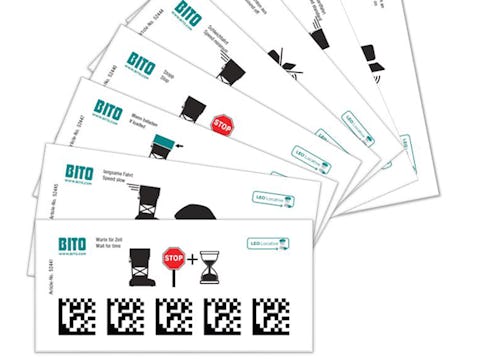

LEO receives its driving commands via the so-called markers, which are simply stuck next to the lane. The markers are labelled with five identical data matrix codes that are read by LEO, which then executes the corresponding command. In addition to the markers, there are other ways to control the LEO system. With the Smart Box, the system's decentralised controller, you can assign different destinations to the transporter. The Smart Box also regulates traffic so that there are no collisions with multiple vans at junctions or bottlenecks.