What is LEO flow?

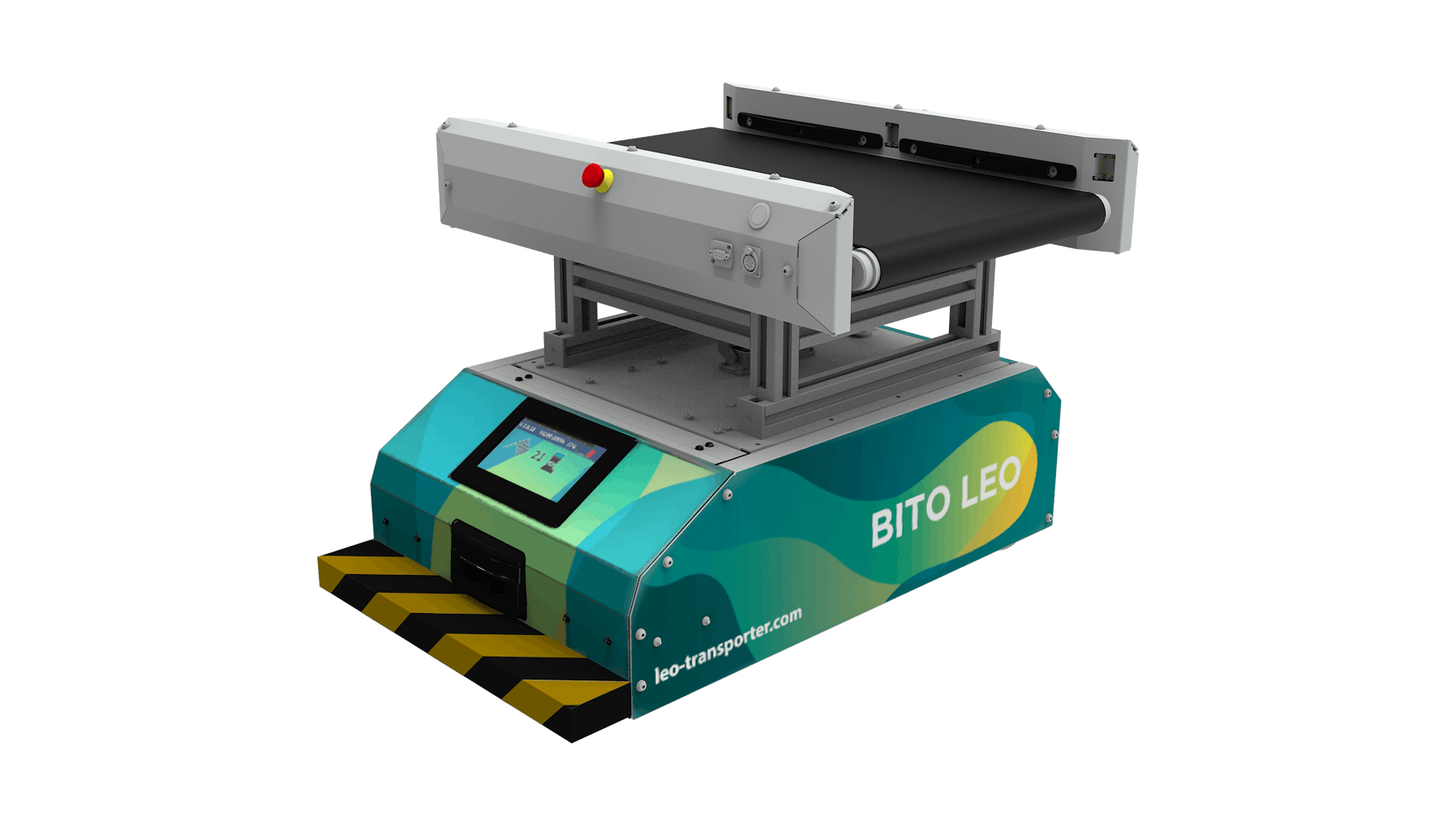

Based on the standard LEO Transporter, LEO flow is part of the LEO product family and is characterised by its belt conveyor This makes it possible to pick up and drop off containers and cardboard boxes from the side. This makes LEO flow the ideal addition to existing conveyor systems or automatically operated workstations. LEO flow can also connect different conveyor systems. Thanks to the automatic height adjustment of the container holder, LEO flow can be combined with a wide range of conveyor systems.

- 35 kg load capacity

- Load up to 800x600 mm

- Height-adjustable

All information about the BITO LEO

Information, tips and advice on the BITO LEO

Download LEO Profi

Discover valuable information about the BITO LEO! Download this free document and get useful tips and advice. Use this practical resource for a comprehensive overview and in-depth insights into all LEO products.

Download the document now!

Just one more click. To send you the requested document by e-mail, we need your name and e-mail address:

Leadmagnet Default Form

Done! The requested document is on its way to you.

If you do not receive the email in your inbox, please check your spam or junk mail folder.

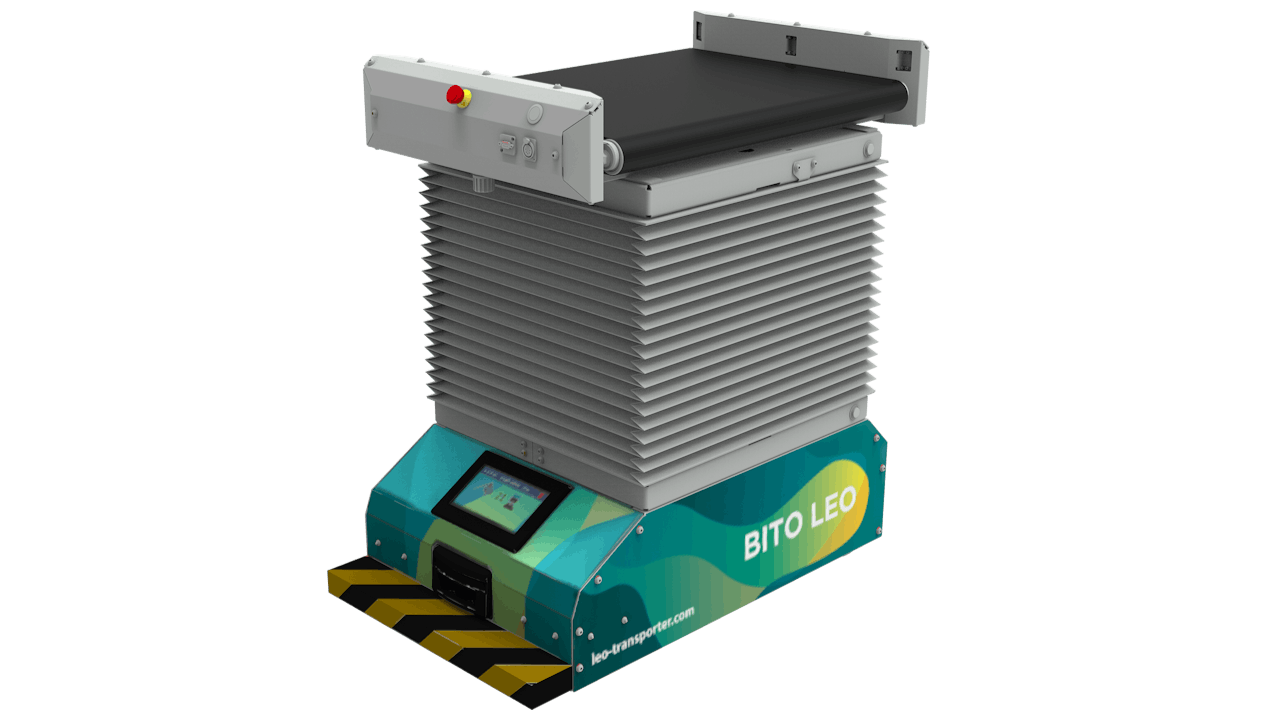

LEO flow with and without lift

LEO flow without lift

- Available with fixed load handling height

- The containers are transported at right angles to the direction of travel

- The load is moved with the long side at right angles to the conveyor system

LEO flow with lift

- Available with dynamic height adjustment from 500 to 1,150 mm

- The containers are transported at right angles to the direction of travel

- The load is moved with the long side at right angles to the conveyor system

Book an appointment!

Use our online booking calendar to arrange an appointment with our BITO LEO experts.

How does LEO flow work?

LEO flow works without any transfer stations

Load detection

LEO flow can detect the status and position of containers and cardboard boxes using three load sensors. LEO flow can therefore recognise whether the container is in position or whether it is being picked up from the right or left side. LEO flow also recognises whether a container is being moved to the left or right side.

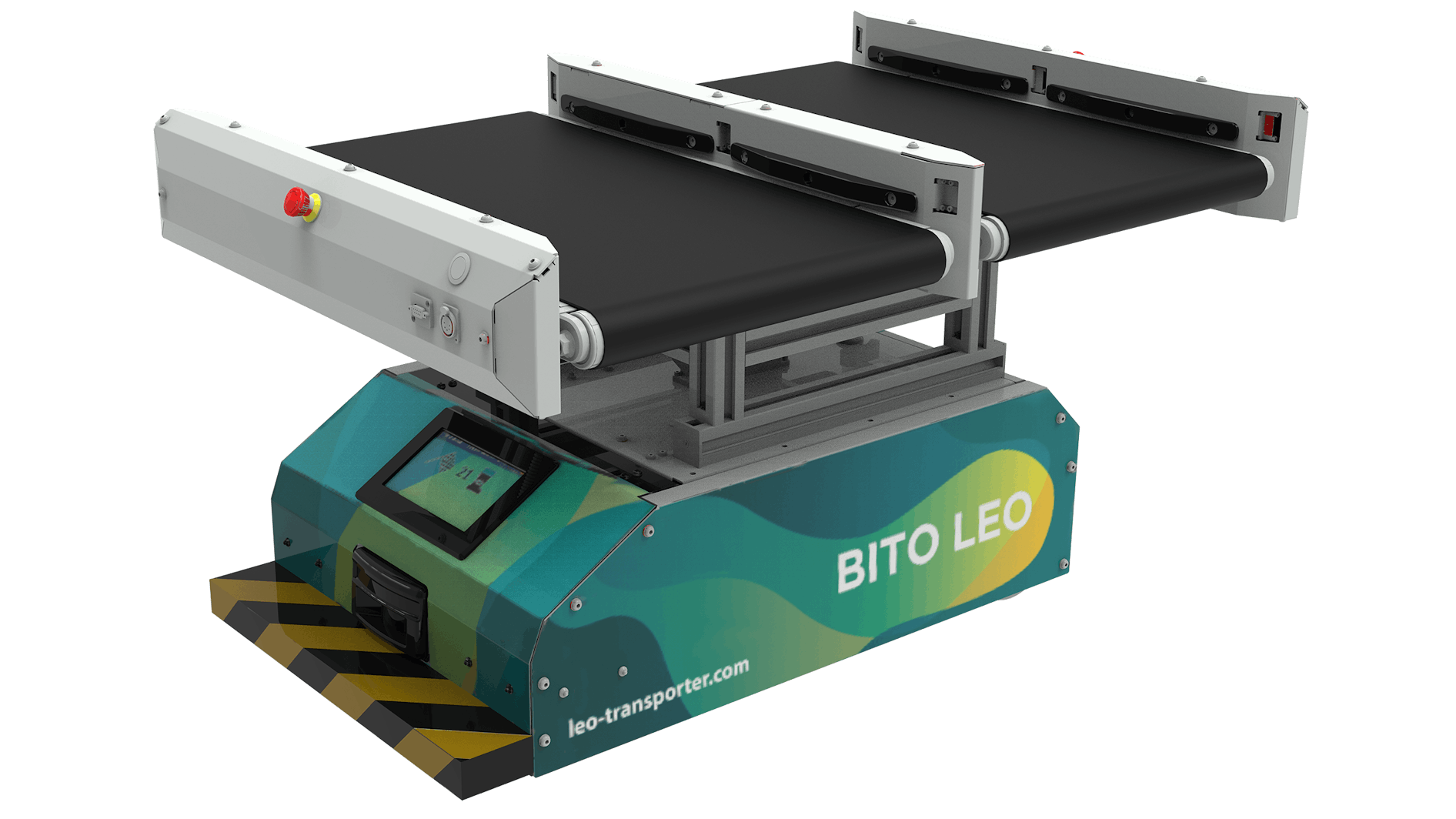

Picking up and dropping off containers

The driven rollers of the LEO flow can discharge the containers both to the right and to the left. It is also possible to pick up external conveyor systems using the same principle.

Height adjustment

The height of the LEO flow body is standardised. The transporter can be optionally equipped with dynamic and automatic height adjustment.

Energy supply

The transporter and its superstructure are powered by the LEO battery. To ensure ideal performance, we recommend automatic charging.

Have we aroused your interest?

Please feel free to contact us. We look forward to your enquiry:

Smart Box as an interface between LEO flow and your conveyor system

To optimise communication between LEO flow and your conveyor system, the Smart Box is connected to your conveyor technology. In this way, LEO is informed whether the conveyor belt is occupied and whether acceptance or delivery is possible. Destination information can also be received from the Smart Box via LEO flow using an external controller.

The document status is checked using various light reflection sensors so that LEO flow knows at all times whether acceptance or delivery is possible. Communication takes place via the Smart Box.

LEO flow can also be optionally equipped with various push buttons. Various commands can be triggered by pressing the push buttons, such as starting up from a standstill or activating selected destinations.

The Smart Box can also be connected to push buttons, which can call or activate LEO flow within a range of around 10 metres.